Summary

A leading plumbing products manufacturer in the United States modernized their ERP system from AX 2009 to Dynamics 365, overcoming significant operational inefficiencies and gaining advanced functionalities to streamline warehouse and pricing operations.

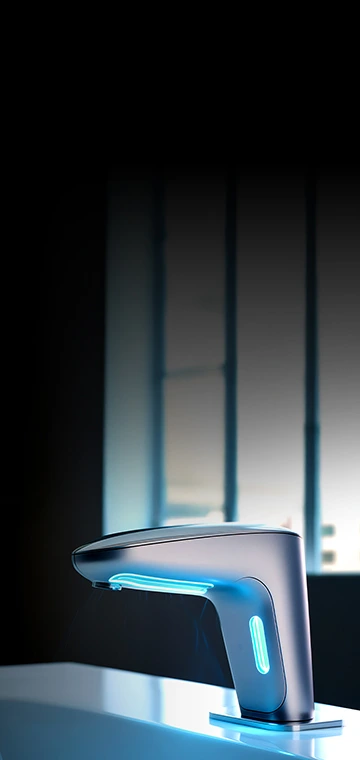

About the Customer

A leading US-based plumbing and drainage products manufacturer with $898M in revenue, 5100 employees, and operations across the United States and Canada.

Pressure Points

The client faced operational inefficiencies due to an outdated ERP system, manual management of critical functions, and inability to handle complex pricing calculations.

Outdated ERP system (AX 2009): Hindered expansion and operational efficiency

Manual warehouse assembly and kitting: Delays in operations and project site deliveries

Legacy ERP's lack of complex pricing support: Loss of control over profit margins

The client aimed to overcome operational challenges by transitioning to the latest ERP version for enhanced vendor support and efficiency. They sought to fully utilize the advanced features of the new system to automate and optimize business processes, particularly in warehouse assembly, kitting, and pricing.

Solutions

Analyzed existing business processes within AX-2009, assessing ERP customization needs.

Developed a tailored migration plan for seamless transition to Dynamics 365 Supply Chain and Operations.

Mapped client's processes to Dynamics 365 features, integrating advanced Warehousing functionalities.

Automated key processes like kitting and pricing, enhancing operational efficiency and aligning with client's business needs.

Implemented full warehouse automation using handheld devices, transforming operational landscape.

Deployed Sonata's Modern Distribution IP with pricing simulator engine, improving profit margin control.

Technology Used

- Dynamics 365 Supply Chain and Finance

- Advanced Warehousing

- Modern Distribution IP

- IoT sensor integration

- Pricing engine integration

Results that Speak Volumes

Automated warehouse operations with handheld devices

Improved kitting functionality for faster deliveries

Better control on margins with 13-level pricing pyramid engine

Enhanced profit margin control through pricing simulator engine

Real-time visibility of products and inventories

Direct sync with construction sites for replenishments and inventory tracking

By the Numbers

230,000

bins across 60 warehouses enabled with RFID technology

~2000

additional business orders processed per month

10%

improvement in warehouse shop floor efficiency

1000

users and 100 distribution centers migrated to D365